| REMARK: |

Product overview: collection of spray drying / fluidized granulation in one, realize the liquid material by one step method particle. Using spray process, especially for micro materials, heat sensitive materials, efficacy than FL boiling granulating machine is 1 to 2 times higher.

[features]

In spray drying / fluidized granulation in one, realize the liquid material by one step method particle. Using spray process, especially for micro materials, heat sensitive materials, efficacy than FL boiling granulating machine is 1 to 2 times higher. Final product water is up to 0.1%, with return powder device, granulation rate is more than or equal to 95%, of 0.2mm particles. Design improvements in mixed fluid atomizer, deal with concrete proportion of 1.3g/cm3.

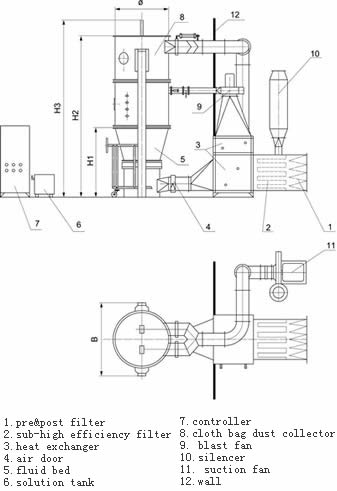

[installation sketch map]

[application]

Pharmaceutical industry: tablets, granules, capsules, granules, low sugar, sugar free Chinese medicine granules. Food: cocoa, coffee, milk powder, granule juice, spices, etc. other industries: pesticides, beverages, fertilizers, pigments, dyes and so on.

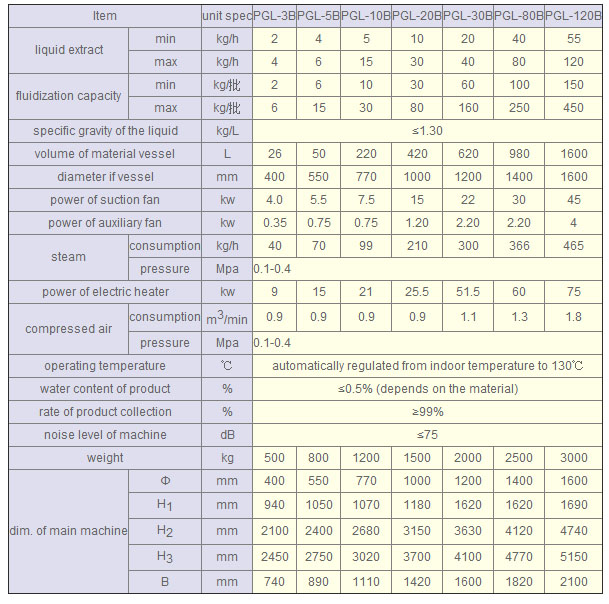

[technical parameter]

Selection: each batch processing flow quantity of extract I=120kg (including solid content is 30%), seed weight II=60kg, by I, II that theory of the weight of the finished M=mI mII=120kgx30% 60kg=96kg, work time T=120kg/30kg/h=4h, bar technical parameters can be found boiling amount for a range of standard load, so to complete two batches of each class, choose PGL-30 is more suitable for.

|